Just over 18 months ago, Intel launched their significantly revised ATX v3.0 power supply standard, and with it, the 600 Watt-capable 12VHPWR cable to power video cards and other high-drain add-in cards. The release of the standard came with a lot of fanfare and excitement – the industry was preparing for a future where even flagship video cards could go back to being powered by a single cable – but shortly after, things became exciting again for all the wrong reasons.

The new 12VHPWR connector proved to be less forgiving of poor connections between cables and devices than envisioned. With hundreds of watts flowing through the relatively small pins – and critically, insufficient means to detect a poor connection – a bad connection could result in a thermal runaway scenario, i.e. a melted connector. And while the issue was an edge case overall, affecting a fraction of a fraction of systems, even a fraction is too much when you’re starting from millions of PCs, never mind the unhappy customers with broken video cards.

So the PC industry is taking a mulligan on the matter, quickly revising the ATX specification and the 12VHPWR connector to fix their design flaws. In its place we have the new ATX v.3.1 power supply specification, as well as the associated 12V-2×6 connector, the combination of which are intended to serve the same goals, but with far less of a chance of errant electricity causing damage.

Ultimately, the combination of the two new standards has required backwards-compatible changes on both the device (video card) side, as well as the power supply side. And as a result, power supply manufacturers are now in the process of releasing ATX v3.1-compliant PSUs that implement these revisions. For PSU vendors, the changes are relatively trivial overall, but they are none the less important changes that for multiple reasons, they are making sure to promote.

Getting down to business, the first ATX v3.1 power supply to enter our testing labs comes from ADATA sub-brand XPG, a prolific player in the PSU market. XPG recently expanded its product lineup with the introduction of the Core Reactor II VE series, the company’s first foray into ATX 3.1-compliant PSUs. As a direct successor of the Core Reactor II series, the Core Reactor II VE is a relatively simple 80Plus Gold unit that distinguishes itself with its straightforward design, aimed at providing steady performance without the high expense.

In today’s review, we are taking a look at the 850W version of the Core Reactor II VE series, which is, for the time being, the most powerful ATX 3.1 unit XPG offers.

| XPG Core Reactor II VE 850W Power specifications ( Rated @ 40 °C ) |

|||||

| RAIL | +3.3V | +5V | +12V | +5Vsb | -12V |

| MAX OUTPUT | 22A | 22A | 70.8A | 3A | 0.3A |

| 120W | 850W | 15W | 3.6W | ||

| TOTAL | 850W | ||||

| 80PLUS RATING | Gold | ||||

| AC INPUT | 100 – 240 VAC, 50 – 60 Hz | ||||

| MSRP | $119 | ||||

The XPG Core Reactor II VE 850W PSU features robust and visually appealing packaging. The box, made from durable cardboard, is adorned in a vivid red color and prominently showcases an image of the unit on the front. To ensure the PSU is well-protected during transport, it is securely encased in dense packaging foam.

The bundle is straightforward, containing just essential components such as mounting screws and the necessary AC power cable. Additionally, it includes several decorative stickers to add a touch of personalization.

This PSU features a fully modular design, which enables the removal of all DC power cables, including the 24-pin ATX connector. The cables are uniformly black, from their connectors to the wires, and are designed without sleeving, resulting in a consistent visual aesthetic.

| XPG Core Reactor II VE 850W | ||

| Connector type | Hardwired | Modular |

| ATX 24 Pin | – | 1 |

| EPS 4+4 Pin | – | 2 |

| EPS 8 Pin | – | – |

| PCI-E 5.0 (12V-2×6) |

– | 1 |

| PCI-E 8 Pin | – | 3 |

| SATA | – | 6 |

| Molex | – | 2 |

| Floppy | – | – |

External Appearance

The XPG Core Reactor II VE 850W PSU is encased in a chassis that measures 86 mm × 150 mm × 140 mm (H × W × D), aligning with the standard ATX dimensions. This relatively compact size enables the power supply unit to fit seamlessly into most tower PC cases. XPG’s engineers were forced to use a 120 mm fan for cooling, as a larger fan does not fit in such a small chassis.

Opting for a subtle aesthetic, the Core Reactor II VE 850W PSU features a sleek matte black finish. The design maintains a refined appearance, enhanced by embossed geometric patterns on the sides and an abstract geometric fan cutout that adds visual interest. The top of the unit displays a detailed sticker that provides its electrical specifications and certifications.

The front side of the XPG Core Reactor II VE 850W PSU hosts only the standard on/off switch and AC receptacle. The modular cable connectors are neatly organized on the rear of the unit, facilitating easy and mistake-free connections. Although the connectors are not color-coded, they are enclosed by a clearly printed, bright white legend on the chassis, which assists in precise cable installation.

Internal Design

The XPG Core Reactor II VE 850W PSU is equipped with a Hong Hua HA1225H12F-Z 120 mm fan, which includes an FDB (Fluid Dynamic Bearing) engine. This type of fan is favored by manufacturers of high-quality PSUs. The fan in this model can reach a maximum speed of 2200 RPM, an impressive figure for a 120 mm fan. The manufacturer’s website states that there should be a 2400 RPM fan installed but that probably was a typographic error.

The XPG Core Reactor II VE 850W ATX 3.1 PSU is manufactured by Channel-Well Technologies (CWT), a renowned OEM known for its capability in producing mid to high power output PC power supplies. CWT’s reputation as a respected OEM is firmly established, with their platforms being integral to some of the most popular power supply units on the market. We can also see that the same exact platform was used for the Core Reactor II 850W ATX 3.0 PSU, verifying that the difference between the ATX 3.0 and ATX 3.1 standards are very subtle, primarily reduced to the length of the PCI-Express 5.0 connector sense pins and their configuration. If anything, the quality went down a bit compared to the ATX 3.0 version of the series, as we can see that higher quality passive components were being used.

The Core Reactor II VE 850W PSU employs well-established topologies, ensuring reliable performance without unexpected deviations. The input stage of the power supply features a more robust transient filter than the ATX design guide baseline, equipped with four Y capacitors, two X capacitors, but just one filtering inductor, followed by two bridge rectifiers on their dedicated heatsink. A copper sheet shields the filtering stage from the rest of the unit. The Active Power Factor Correction (APFC) circuit active components lie on the primary heatsink along the edge of the PCB. The active APFC components are two 33N60M2 MOSFETs and a diode, along with a filtering inductor and a massive 400V/680μF capacitor from Elite.

In the primary inversion stage, the Core Reactor II VE 850W PSU utilizes a half-bridge LLC topology with main switchers (25N60EFL) mounted on a dedicated heatsink, a typical setup in contemporary power supplies for its cost-effectiveness and reliability. The secondary stage conversion features eight OnSemi NTMFS5C430N transistors on a vertical daughterboard, delivering a single 12V output. The 3.3V and 5V rails are managed by DC-to-DC conversion circuits on another daughterboard.

On the secondary side, the PSU incorporates a mix of both electrolytic and solid-state capacitors from Elite and CapXon, both of which are known but are not considered to be amongst the most premium capacitor manufacturers. The ATX 3.0 version of the series featured capacitors from Japanese manufacturers instead.

The ATX v3.1 specification was officially launched on 13 September 2023, following the release of the ATX v3.0 in February 2022. The new specification includes the PCIe Card Electromechanical Specification Revision 5.1 (or PCI-SIG CEM 5.1) and complies with all previous Engineering Change Notices (ECNs) from PCI-SIG.

The primary purpose of the updated specification is to standardize that power supplies switch over from the 12VHPWR connector to the newer 12V-2×6 connector. Though there are a few other interesting changes as well, including some changes that lighten the burden of PSUs.

Nonetheless, the differences between Intel’s ATX 3.1 and ATX 3.0 specifications are largely superficial, primarily involving minor updates rather than substantial changes. ATX 3.1 mostly introduces nuanced adjustments to power requirements and connector specifications, which do not radically alter the foundational architecture or the overall performance standards established by ATX 3.0.

The 12V-2×6 Connector: Longer Sense Pins For Safer Power

The most prominent change in ATX v3.1 undoubtedly is the introduction of the 12V-2×6 connector, which is a backwards-compatible connector designed to supplant the quickly-obsoleted 12VHPWR connector. Improving upon the safety risks with the 12VHPWR connector, 12V-2×6 connector implements some mechanical upgrades and new settings for the sense pins, the combination of which is intended to avoid sending power down a poorly connected wire.

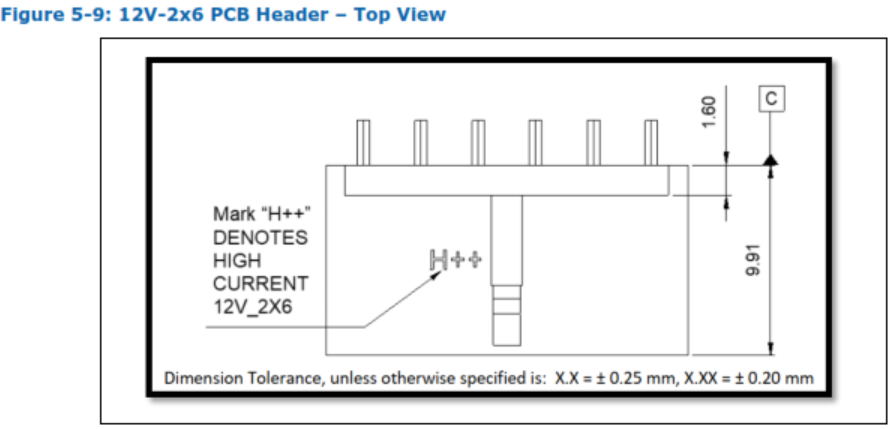

The v3.1 spec provides a detailed overview of the new 12V-2×6 connector through updated figures and sections. Key aspects, such as the power pins’ current rating, connector body labeling, and pin contact material, are explicitly discussed.

Figures 5.3 to 5.9 of the ATX v3.1 specification are new and now exhibit the 12V-2×6 connector. According to the ATX v3.1 specification, the 12V-2×6’s design permits potential support of up to 1324.8W per connector with a maximum temperature delta of 30 Celsius degrees above ambient. The use of copper alloy contacts and 16 AWG cables remains mandatory. Even the latch retention strength remains the same between the two specifications, at 45N for axial pull.

Units with 12V-2×6 connectors must have clear labeling on the connector body (H++). Units with 12VHPWR connectors shall have them labeled as H+.

The new specification also includes a whole paragraph of detailed recommendations for the cable plug connection that encompasses everything from recommending specific crimp contact types to the temperature resistance of the connector and low level contact resistance of the pins. These recommendations were not included in the previous specification, but that doesn’t mean that 12VHPWR connectors do not comply with them, or for that matter that all 12V-2×6 connectors do. Even if it was a requirement instead of a recommendation, we suspect that low-quality products would not comply with those figures.

Broadly speaking, there are no physical differences between the bodies of the 12V-2×6 and 12VHPWR connectors, aside from a minor definition of a second plug housing option with a thumb-ridge design for the sideband signals shroud (Figure 5-3 of the ATX v3.1 specification).

Internally, however, there is a subtle, yet vital difference – the PCB Header’s internal pin lengths have been changed, making the power pins being longer and sense pins shorter. This design ensures a “first-mate/last-break” engagement, meaning the power pins connect before the sideband pins, and disconnect after. Such a sequence is pivotal for ensuring safety – and is something that was either overlooked or underestimated when defining the 12VHPWR connector.

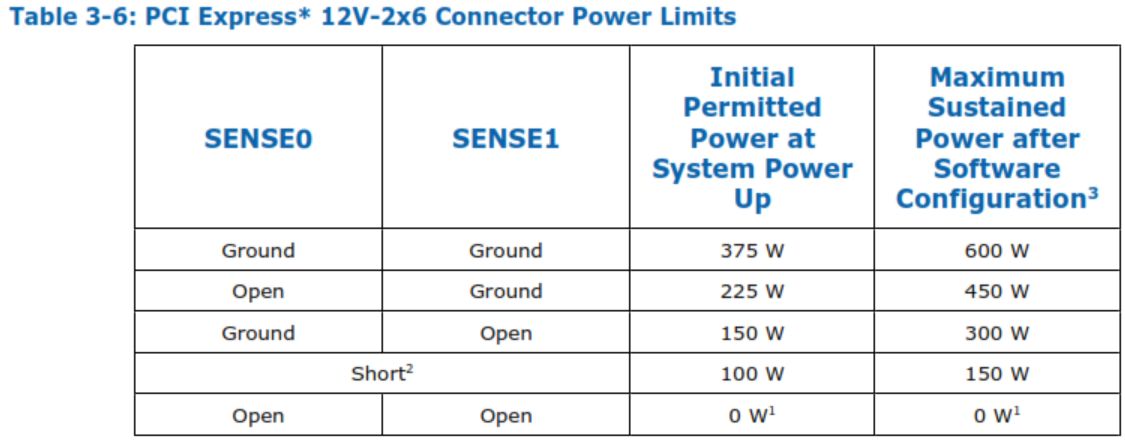

Doubling-down on this shift to safety, how the sense pins are interpreted has also been changed. Now if both sense pins are unconnected (open), the ATX 3.1 standard dictates that devices are not to be supplied any power at all. The basis behind this change being that in scenarios where connectors might be incorrectly attached or completely absent, this configuration prevents a PSU from sending power down the line, effectively avoiding potential connector damage or melting.

Suffice it to say, that is a notable change over the previous specification, where two open sense pins was used to trigger 150W mode. Intended as a compatibility measure with 150W 8-pin PCIe power plugs, using open pins for 150W mode meant that PSUs lacked a good (and mandated) way to tell if there is a reliable connection between the PSU and video card. So this fixes that issue by making the null case to not send any power at all; the sense pins on the PSU side must sense something before the PSU will send down power. Which in the case of the newly displaced 150W mode, now requires the two sense pins to be shorted together.

The changes to the sense pins are a hardware-level change for PSUs, albeit a minor one. Whereas an ATX v3.0 compliant unit would permit up to 150 Watts if both sense pins are disconnected, an ATX v3.1 compliant PSU will not deliver any power at all. Fortunately, besides improving safety, this strategy is designed to be fully backwards compliant, so that 12VHPWR-equipped video cards will still work with the newer PSUs – and for that matter newer video cards with older PSUs as well (albeit without the additional safety of the zero-Watt mode).

As for the cables themselves, these remain unchanged and are fully compatible with the new connector. The only changes are on the device/host sides, and not the copper in the middle that is connecting the two.

Otherwise, 12V-2×6 is not in any way more capable than the 12VHPWR connector in terms of strength and/or power delivery capabilities.

Adding PCIe Slot Power Excursions, Updated Power Delivery Tables

While the chief importance of the ATX v3.1 specification is the introduction of the 12V-2×6 connector, the standard also makes some small, but notable, updates to the power tables that define power excursions for both cables and PCIe slots, and how they’re to be handled.

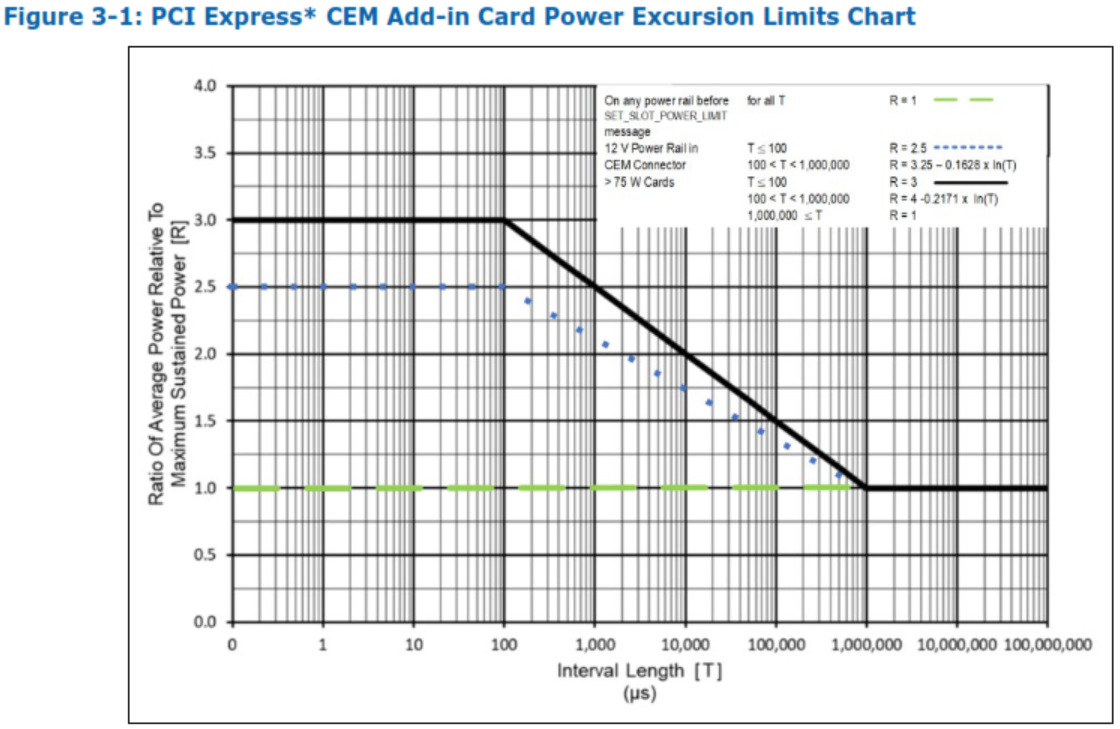

In the v3.1 spec, it is specifically noted that power excursions are permitted from the 12V rail of the PCIe slot. Thus, the 12V rail on the PCIe slot can experience spikes up to 13.75A for up to 100μs (equivalent to 165W). Previously, the limit was a mere 5.5A. The 12V rail can be boosted for up to 1 second using a logarithmic formula included in the new ATX 3.1 specification (Table 3-1). No power excursions are permitted on the 3.3V rails.

Table 3-1 and Figure 3-1 of the specification have been updated to include the power excursion margins of the PCIe slot. We can see that the new figure now includes a blue line specifically for the allowed power excursion over time for the PCIe slot itself. The black line refers to the total power excursion allowed for each individual card (PCIe slot + 12V-2×6 connector).

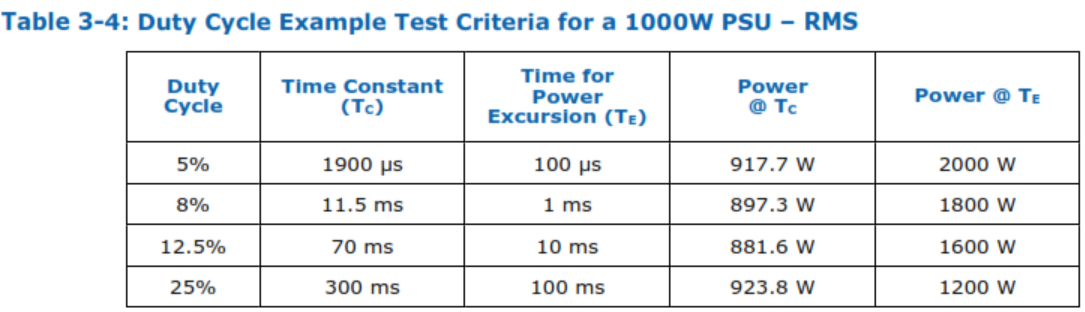

One more interesting change lies with Tables 3-3 and 3-4 which dictate the testing criteria for power excursions, with Intel reducing all of the testing duty cycle times. Although the maximum excursion remains at 200% power over 100 μs for a card with a 12V-2×6 connector, the testing duty cycle has been halved. Oversimplifying this change, it means that the new specification allows for power excursions of the same magnitude but requires twice as much time between excursions.

This could be mistaken as far less strain for the PSU but that is not actually true, as the calculation formula increases the power during the remainder time, resulting to nearly identical RMS power over time. Intel just, for whatever reason, effectively halved the maximum time power excursions should last over the last version.

Intel has also updated Table 3-5 to specifically include all four power modes that the new 12V-2×6 connector can operate at. Previously, the ATX v3.0 specification only presented the 600W/55A option of the 12VHPWR connector.

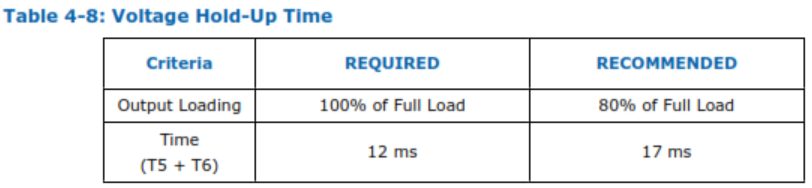

Another change that is indirectly related to the above is the lower Voltage Hold Up times, which can be found in Table 4-8. The ATX v3.1 spec includes a “recommended” hold up time of 17 ms at 80% load next to the required 12 ms at 100% load. These figures are slacker than the previous ATX v3.0 specification, as there was only a required hold up time of 17 ms at 100% load. As relevant hardware (i.e. UPS systems) also improved their reaction times over the years, Intel probably decided that 17 ms is too strict for modern high-power PSUs, unnecessarily requiring them to include too bulky capacitors to even try and comply with the specification. The winners here are the very high output designs that would require very large (i.e., expensive) capacitors to comply and compact unit designers as they can now use smaller capacitors for their platforms.

Ultimately, power supply manufacturers will have very little difficulty adjusting their products to comply with the ATX 3.1 standard, and we suspect that most of the currently available platforms will merely undergo minor tweaking to comply with the zero-Watt mode. ATX 3.0 PSUs will continue being compatible with modern graphics cards, merely lacking the extra safety the 12V-6×6 connector can offer via its first-mate/last-break design. If anything, the brute of the changes will be hitting motherboard designers, as future motherboards needs to comply with the PCIe slot power dynamics. It’s too early to predict what this will mean for future graphics card compatibility, but the addition of 12V power excursions over PCIe slots is not a trite change overall.

For the testing of PSUs, we are using high precision electronic loads with a maximum power draw of 2700 Watts, a Rigol DS5042M 40 MHz oscilloscope, an Extech 380803 power analyzer, two high precision UNI-T UT-325 digital thermometers, an Extech HD600 SPL meter, a self-designed hotbox and various other bits and parts. For a thorough explanation of our testing methodology and more details on our equipment, please refer to our How We Test PSUs – 2014 Pipeline post.

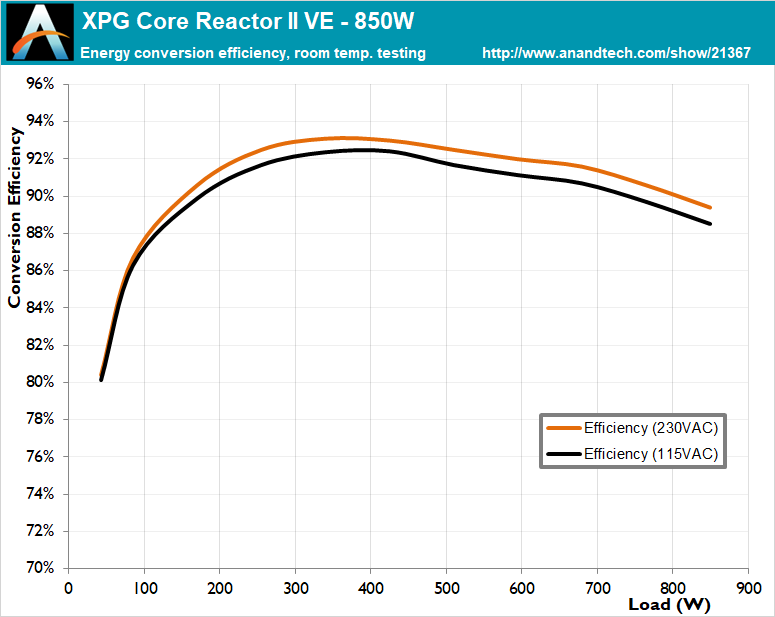

The XPG Core Reactor II VE 850W PSU surpasses the requirements set by the 80Plus Gold certification with impressive margins. When operating with a 115 VAC input, this PSU demonstrates an average nominal load efficiency of 90.9% across a range from 20% to 100% of its capacity, which further increases to 91.7% with a 230 VAC input. The efficiency peaks at a load slightly less than half its maximum capacity. Low load efficiency is excellent, notably superior to that of many other units with a similar power output.

The XPG Core Reactor II VE 850W PSU does not have a “hybrid” fan mode – its fan is operational at all times. Even in ambient room temperature, the fan operates continuously but at very low speeds while the load is low, gradually increasing its speed as the load escalates beyond 500 Watts. This simplistic approach reduces the complexity of the design a little and the PSU virtually remains inaudible while the load is very low.

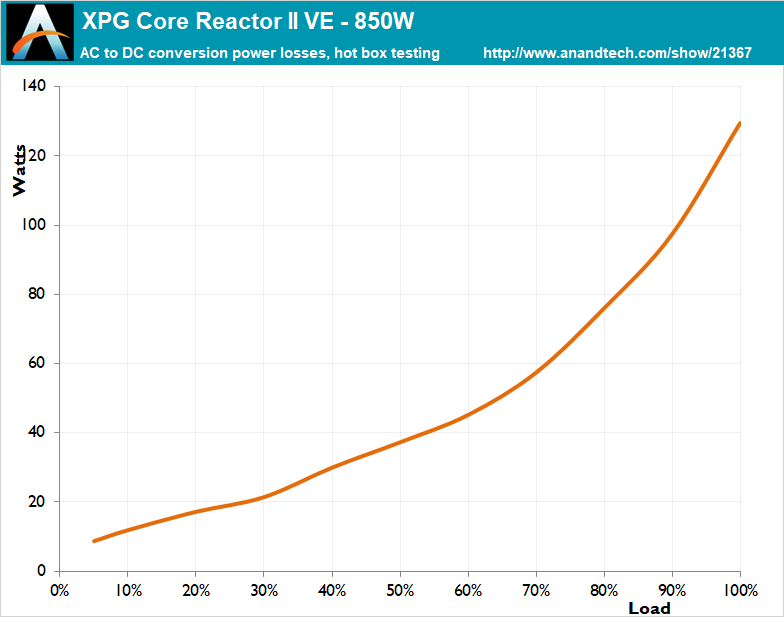

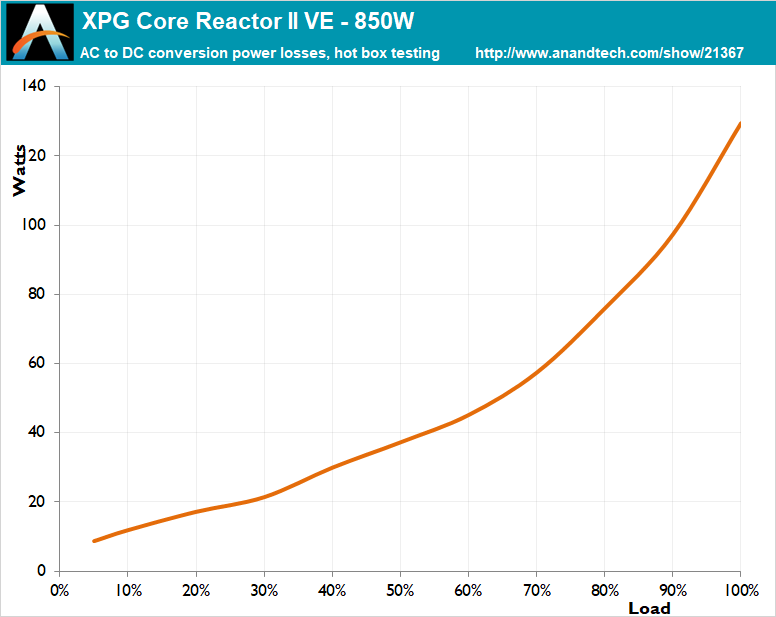

During its hot testing phase, the XPG Core Reactor II VE 850W PSU exhibits a marked decrease in efficiency under heavy loads, with figures dropping to 88.9% under a 115 VAC input and 89.7% with a 230 VAC source, compared to 90.9% and 91.7%, respectively, during cold testing. This significant decline is accentuated at higher load levels and is accompanied by signs of significant thermal stress. Although this PSU is rated for operation at an ambient temperature of up to 40°C, the effect that higher ambient temperatures had on its performance are rather severe.

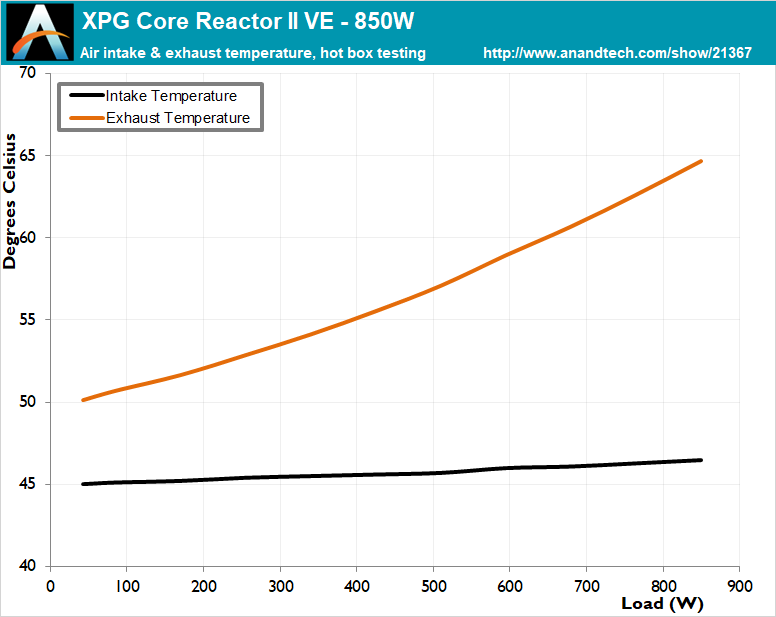

In hot testing conditions, the fan of the XPG Core Reactor II VE 850W PSU operates continuously, at higher speeds than with a low ambient temperature and further increasing its speed as the load surpasses 400 Watts. It also nears its maximum speed as it approaches 80% capacity. This operational characteristic keeps the PSU relatively tolerable up to 60-65% load. However, beyond that point, the noise level rises significantly, making the unit audibly noticeable.

With its 120 mm fan, the XPG Core Reactor II VE 850W PSU effectively handles cooling, but temperatures do become uncomfortably high when the load exceeds 75%. Despite this increase, the temperatures remain below the threshold necessary to trigger the over-temperature protection (OTP). The designer seems to have made a major effort in balancing acoustics and thermal performance/reliability.

The electrical performance of the XPG Core Reactor II VE 850W PSU is competent, with effective voltage regulation across its outputs. However, ripple suppression on the 3.3V and 5V lines shows room for improvement, characterized as mediocre compared to industry leaders. The 12V rail exhibits a maximum ripple of 56 mV, and the ripple on the 5V and 3.3V lines measures at 38 mV and 34 mV respectively, indicating less stringent control compared to some high-end models. Despite this, the PSU maintains stable operation and matches the performance ratings advertised by the manufacturer.

| Main Output | ||||||||

| Load (Watts) | 172.03 W | 429.42 W | 642.42 W | 855.98 W | ||||

| Load (Percent) | 20.24% | 50.52% | 75.58% | 100.7% | ||||

| Amperes | Volts | Amperes | Volts | Amperes | Volts | Amperes | Volts | |

| 3.3 V | 1.99 | 3.3 | 4.97 | 3.3 | 7.45 | 3.28 | 9.94 | 3.28 |

| 5 V | 1.99 | 5.06 | 4.97 | 5.05 | 7.45 | 5.04 | 9.94 | 5.04 |

| 12 V | 12.79 | 12.15 | 31.98 | 12.13 | 47.97 | 12.1 | 63.96 | 12.09 |

| Line | Regulation (20% to 100% load) |

Voltage Ripple (mV) | |||||

| 20% Load | 50% Load | 75% Load | 100% Load | CL1 12V |

CL2 3.3V + 5V |

||

| 3.3V | 0.5% | 14 | 24 | 30 | 34 | 18 | 32 |

| 5V | 0.3% | 12 | 20 | 26 | 38 | 16 | 28 |

| 12V | 0.5% | 16 | 26 | 32 | 56 | 48 | 30 |

During our thorough assessment, we evaluate the essential protection features of every power supply unit we review, including Over Current Protection (OCP), Over Voltage Protection (OVP), Over Power Protection (OPP), and Short Circuit Protection (SCP). The XPG Core Reactor II VE 850W PSU passed all critical protection tests, proving its capability to safeguard against scenarios that could compromise the PSU or connected components. The unit showed slightly loosely calibrated Over Current Protection (OCP) for the 3.3V and 5V rails, activating at 136% and 138% respectively, which is high but remains within acceptable limits. The 12V rail’s OCP activation at 146% is extremely high but we are not surprised considering the need of manufacturers to comply with the power excursion design guide requirements.

The XPG Core Reactor II VE 850W PSU distinguishes itself as the first ATX 3.1-compliant unit from XPG, setting a benchmark in the power supply landscape with its adherence to the latest standards. Priced at an MSRP of $119 and likely to retail for significantly less, this power supply unit blends high-quality performance, robust construction, and a price point that appeals to a broad spectrum of users. Manufactured by the reputable Channel-Well Technologies, the unit benefits from expert craftsmanship, enhancing its durability and ensuring it stands up to the rigors of daily use. The provision of a 7-year warranty by XPG further emphasizes their confidence in the PSU’s long-term reliability.

In terms of performance, the XPG Core Reactor II VE 850W does very well, achieving impressive efficiency ratings that greatly exceed the requirements for 80Plus Gold certification, recording average nominal load efficiencies of 90.9% on 115 VAC and 91.7% on 230 VAC. Power quality is great too, with fantastic voltage regulation on all lines and good filtering on the primary 12V line. Despite its strengths, it is worth mentioning that the unit does exhibit only moderate ripple suppression on the 3.3V and 5V lines, which may be adequate but not on par with other high tier products.

Thermal management in the Core Reactor II VE is acceptable, mostly thanks to its powerful 120 mm fan, which effectively dissipates heat across varying loads. However, the unit’s electrical performance does show signs of degradation under extreme conditions due to thermal stress, particularly when operating near full capacity in higher ambient temperatures. This aspect is crucial for users to consider, especially those in warmer climates or with high-load applications, as it impacts both performance and noise levels, with the latter increasing significantly under heavy loads.

In conclusion, the XPG Core Reactor II VE 850W PSU is a significant release, being the first to meet ATX 3.1 specifications, seemingly offering forward-looking compatibility with next-generation hardware. The balance of cost, capabilities, and the extended warranty make it an attractive option for a wide range of users, from gamers to professional workstation builders. While it performs admirably across most parameters, potential buyers should weigh the implications of its poor performance under adverse operating conditions. Still, its performance metrics under typical operating conditions and quality make it a worthy investment for those who want a balanced product that does not break the bank.